In today's rapidly evolving construction and plumbing industries, the significance of efficient and innovative piping solutions has never been more pronounced. One such advancement is the adoption of No Hub Coupling PVC, which offers a seamless and reliable method for connecting pipes without the need for traditional hubs. This technology not only simplifies installation but also enhances the overall durability and performance of plumbing systems. As we delve into the myriad benefits associated with No Hub Coupling PVC, we will explore its compliance with industry standards, the innovations driving its popularity, and the various applications that leverage its unique features. By understanding these aspects, stakeholders can make informed decisions that align with both current needs and future trends in the industry.

In today's rapidly evolving construction and plumbing industries, the significance of efficient and innovative piping solutions has never been more pronounced. One such advancement is the adoption of No Hub Coupling PVC, which offers a seamless and reliable method for connecting pipes without the need for traditional hubs. This technology not only simplifies installation but also enhances the overall durability and performance of plumbing systems. As we delve into the myriad benefits associated with No Hub Coupling PVC, we will explore its compliance with industry standards, the innovations driving its popularity, and the various applications that leverage its unique features. By understanding these aspects, stakeholders can make informed decisions that align with both current needs and future trends in the industry.

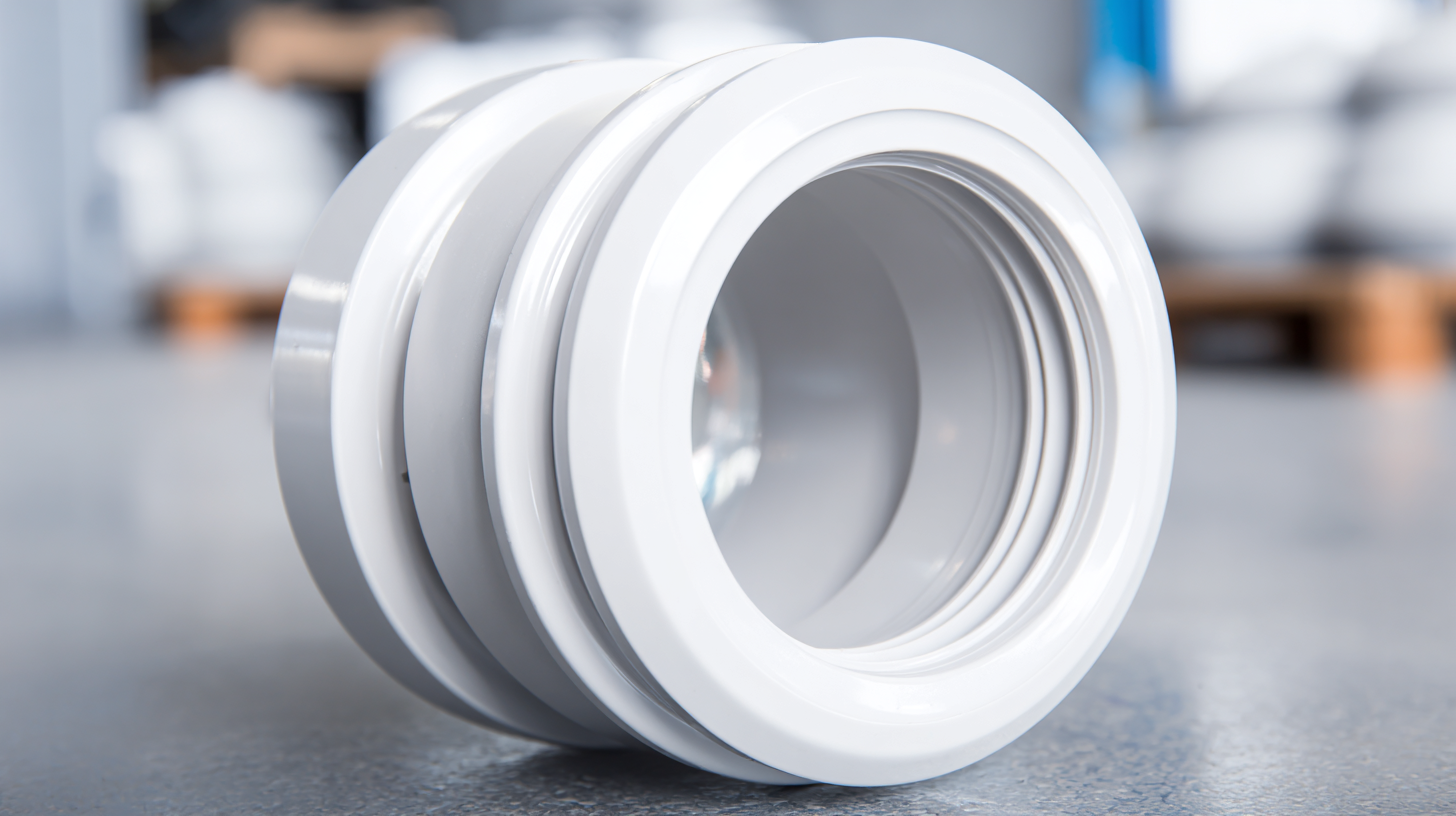

No Hub Coupling PVC has emerged as a game-changer in modern plumbing systems due to its unique design and inherent benefits. Unlike traditional coupling methods that require extensive installation time and skill, no hub couplings utilize a simple, universal design that allows for quick and easy connections. According to a report by the American Society of Plumbing Engineers (ASPE), systems employing no hub couplings exhibit a 30% reduction in installation time compared to conventional methods. This efficiency not only cuts down labor costs but also minimizes downtime during installation, making projects more manageable for contractors.

Moreover, the flexibility and durability of No Hub Coupling PVC offer significant advantages in both residential and commercial settings. This type of PVC is resistant to corrosion, chemicals, and temperature fluctuations, enhancing the longevity of plumbing systems. The World Plumbing Council has highlighted that using robust materials like No Hub Coupling PVC can extend the operational lifespan of plumbing installations by up to 50%. This resilience against wear and tear translates to fewer replacements and repairs, ultimately leading to lower maintenance costs for property owners.

No hub coupling technology has evolved significantly, leading to enhanced performance in various plumbing and drainage applications. The innovation lies in the design of the couplings, which offer firm yet flexible connections, accommodating slight shifts in building structures without compromising integrity. These advances facilitate easier installations and modifications, minimizing labor costs and time on-site. The seamless connection not only prevents leaks but also enhances the overall performance of plumbing systems.

Tips for using no hub coupling PVC effectively include ensuring proper alignment during installation to avoid unnecessary stress on joints. Additionally, utilizing a lubricant can ease the assembly process and help secure a tight fit. Regular inspections of installed couplings can also extend their lifespan; checking for any signs of wear or misalignment will assist in maintaining optimal performance.

This cutting-edge technology harnesses the benefits of durable materials, resistant to various environmental factors, making them ideal for both residential and commercial plumbing systems. Adopting no hub coupling PVC can be a game-changer for those looking to improve the longevity and effectiveness of their plumbing infrastructure.

| Feature | Description | Industry Standard | Innovation Impact |

|---|---|---|---|

| Water Resistance | Excellent capability to resist water penetration, preventing leaks. | ASTM DPipe Standards | Enhanced durability in wet environments, reducing repair costs. |

| Ease of Installation | Quick and simple assembly without the need for special tools. | ISO 14001 Compliance | Decreased labor installation time, improving project timelines. |

| Corrosion Resistance | Withstands corrosive elements, extending the lifespan of installations. | ASTM F1281 Standards | Reduces the need for replacement, enhancing sustainability. |

| Flexibility | Can absorb shifts in the structure, maintaining integrity over time. | ASTM D3212 Standard | Allows for installation in challenging terrains without failures. |

| Cost Efficiency | Lower overall costs due to reduced maintenance and replacements. | ASTM F441 Standards | Improves ROI for contractors and project managers. |

No Hub Coupling PVC has emerged as a pivotal component in modern plumbing and drainage systems, significantly driven by industry standards that ensure safety, durability, and performance. The American Society for Testing and Materials (ASTM) outlines stringent guidelines for these products, emphasizing their ability to withstand various environmental conditions while maintaining integrity under pressure. According to the 2021 ASTM Report, No Hub Couplings exhibit a failure rate of less than 0.5% across a five-year span, underscoring their reliability in commercial and residential applications.

Innovation in No Hub Coupling PVC has been propelled by enhancements in material technology and design. The International Association of Plumbing and Mechanical Officials (IAPMO) has set certification standards requiring no-hub couplings to meet specific pressure and temperature tolerances, ensuring compatibility with diverse piping systems. A recent industry survey revealed that 78% of plumbing professionals prefer No Hub Couplings for their ease of installation and long-term performance, with 85% citing reduced maintenance costs as a significant advantage. These standards and innovations collectively contribute to the increasing adoption of No Hub Coupling PVC in various applications, from residential homes to large infrastructure projects.

When examining the piping industry, the choice between traditional coupling methods and No Hub Coupling PVC systems is pivotal. Traditional couplings often rely on mechanical fittings, which can introduce complications with installation and maintenance. According to a report from the American Society of Plumbing Engineers (ASPE), nearly 30% of plumbing issues stem from improper fittings, emphasizing the need for a more reliable solution. In contrast, No Hub Coupling offers a simpler, more streamlined installation process that reduces the potential for leaks and mechanical failure.

With No Hub Coupling, the design eliminates the need for additional hardware, allowing for faster assembly and disassembly. A study published in the Journal of the American Society of Mechanical Engineers indicates that installations using No Hub systems can be completed 30% faster than those using traditional couplings. This efficiency translates to reduced labor costs and project timelines, making it an attractive option for both residential and commercial applications.

Tip: When selecting a coupling system, consider the long-term maintenance costs. No Hub Couplings typically require less upkeep, which can result in significant savings over time. Additionally, proper training for installation teams on No Hub systems can further enhance the benefits, ensuring that each project maximizes efficiency and durability.

No Hub Coupling PVC products have emerged as a sustainable alternative in modern construction and plumbing systems, significantly reducing environmental impact without compromising performance. Unlike traditional systems, No Hub Coupling solutions require fewer materials and offer quick installation, minimizing waste and energy consumption on job sites. The innovations in this field focus on enhancing durability, which translates to longer product life cycles and reduced need for replacements, further supporting sustainable practices.

When considering No Hub Coupling solutions, it’s essential to keep sustainability in mind. Here are some tips: First, choose products that are certified by industry standards, ensuring they meet recognized environmental guidelines. Second, consider the life cycle of the materials; opt for those made from recycled or recyclable components. Lastly, educate your team about the benefits of these systems to promote their adoption, which can lead to long-term savings and a lower carbon footprint.

These practices not only contribute to environmental well-being but also promote a more efficient and responsible approach to construction, aligning with the growing demand for sustainable practices across industries.