In today's fast-paced industrial environment, optimizing machinery performance is crucial for maintaining competitiveness and operational efficiency. Research indicates that improper coupling solutions can lead to significant efficiency losses, with studies showing that up to 30% of energy consumption in machinery operations is attributed to poor alignment and ineffective coupling systems. Hub Coupling solutions have emerged as a vital component in enhancing machinery performance, offering benefits such as increased torque capacity, vibration dampening, and misalignment tolerance. By adopting advanced Hub Coupling technologies, industries are witnessing a marked improvement in production reliability and a reduction in downtime. As reported by the International Society of Automation, organizations that implement optimized coupling systems can experience up to a 20% increase in overall equipment effectiveness. This article will explore practical strategies for leveraging Hub Coupling to maximize machinery performance and drive operational excellence.

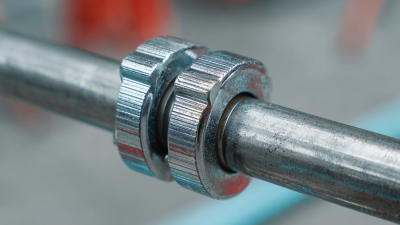

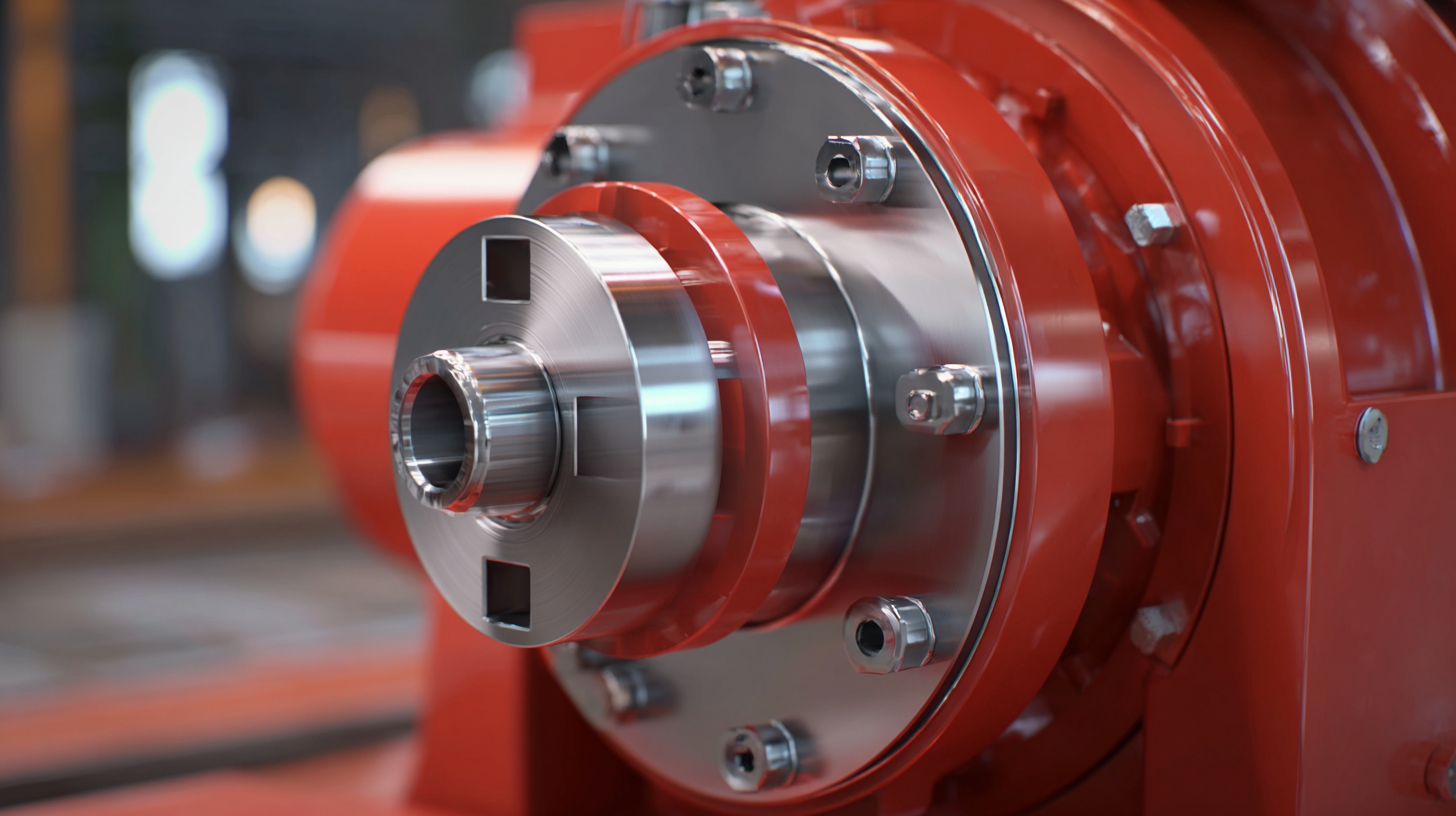

Hub coupling plays a crucial role in optimizing machinery performance by providing a reliable connection between rotating shafts. Understanding the nuances of hub coupling technology helps industries enhance operational efficiency and reliability. Couplings designed for specific applications, such as marine electric and hybrid propulsion systems, are particularly significant as they must be lightweight and electrically insulated. These specific requirements are essential for ensuring seamless power transmission and reducing overall system weight, which can lead to improved fuel efficiency.

Recent advancements in coupling technology, such as the introduction of new composite disc flexible shaft couplings, bring additional benefits to the table. These innovative couplings not only accommodate various shaft misalignments but also handle high torque applications effectively. According to industry reports, the demand for lightweight and specialized couplings is growing, driven by the rise of electric and hybrid systems that require high performance without compromising on safety. Implementing these advanced hub coupling solutions can lead to superior machinery performance, reduced maintenance costs, and enhanced longevity of critical components in various industrial landscapes.

Implementing hub coupling solutions in your operations can significantly enhance machinery performance. One of the key benefits is the improvement in transmission efficiency. According to a recent study by the International Organization for Standardization (ISO), systems that incorporate high-quality hub couplings can improve power transmission efficiency by up to 15%. This efficiency boost not only results in reduced energy consumption but also contributes to lower operational costs over time.

Another advantage of hub coupling solutions is their ability to absorb misalignment and vibrations, which are common causes of equipment wear. Research by the Machinery and Equipment Manufacturers Association (MEMA) states that coupling misalignment is responsible for approximately 50% of premature mechanical failures in rotating machinery. By utilizing flexible hub couplings, companies can enhance the lifespan of their equipment, minimizing both downtime and maintenance expenses.

Tips:

1. Regularly monitor the alignment of your machinery to prevent unnecessary wear and tear.

2. Choose the appropriate hub coupling type that suits your specific machinery requirements for better performance.

3. Invest in quality couplings, as the upfront cost can lead to significant savings in energy and maintenance in the long run.

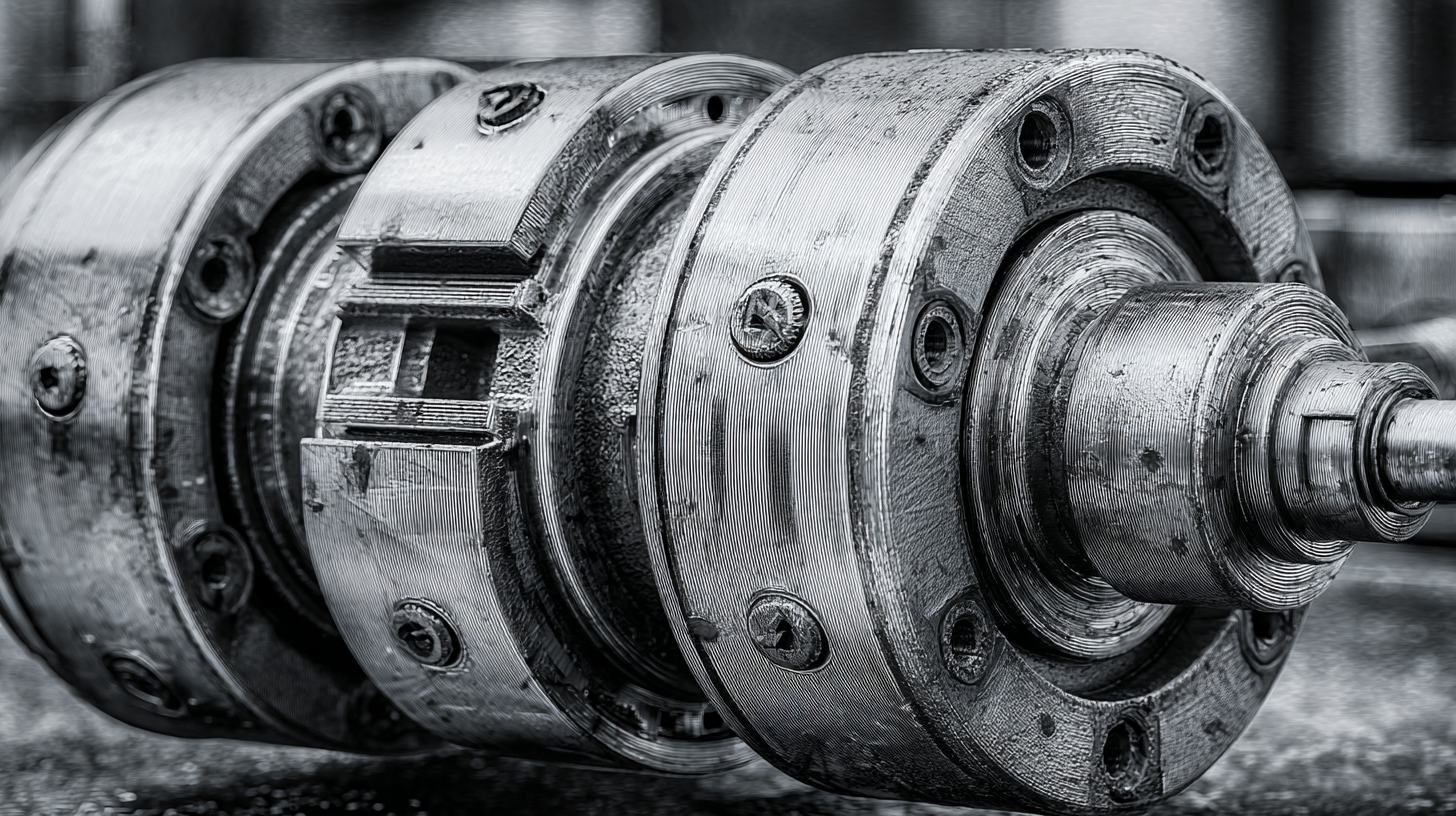

Assessing current machinery performance is crucial for identifying specific needs and enhancing efficiency through hub coupling solutions. According to a 2022 report by the Machinery Optimization Institute, nearly 40% of machinery failures are attributed to misalignments and inadequate coupling systems. Start by conducting a comprehensive analysis of your machinery's operational metrics, including vibration levels, temperature readings, and overall efficiency. Utilize tools such as vibration analysis and thermal imaging to gather data, which can reveal hidden issues affecting performance.

Once data is collected, compare it against industry benchmarks. The American Society of Mechanical Engineers (ASME) states that optimal coupling solutions can increase machinery lifespan by up to 30% and reduce maintenance costs by 20%. Identify any deviations in performance metrics and classify them into categories such as wear and tear, misalignment, or excessive loads. By aligning your machinery’s performance against these industry standards, it becomes easier to pinpoint necessary improvements. This structured approach ensures that the solutions you implement are data-driven and tailored to your machinery's unique operational needs.

When optimizing machinery performance, the installation and maintenance of hub couplings play a crucial role. Proper alignment during installation is essential; misalignment can lead to increased wear and tear, reducing the lifespan of both the coupling and the connected machinery. According to a report by the American Society of Mechanical Engineers, nearly 45% of machinery failures can be attributed to improper alignment. Utilizing laser alignment tools can enhance precision, ensuring that couplings function smoothly and efficiently.

Regular maintenance of hub couplings is also vital for sustained performance. A study from the International Journal of Mechanical Engineering revealed that routine inspections and servicing can boost machinery efficiency by up to 30%. Key practices should include checking for signs of wear, ensuring lubrication is adequate, and replacing worn components promptly. Implementing a predictive maintenance strategy, integrating sensors for real-time data monitoring, can further preempt potential failures, thereby maximizing operational uptime and reducing overall costs. By adhering to these best practices, organizations can significantly enhance the reliability and efficiency of their machinery through effective hub coupling solutions.

| Aspect | Description | Best Practices | Maintenance Tips |

|---|---|---|---|

| Alignment | Proper alignment between connected shafts. | Use laser alignment tools to achieve precision. | Check alignment regularly, especially after maintenance. |

| Torque | Correct torque application on coupling bolts. | Follow manufacturer specifications for torque settings. | Re-check torque levels periodically to prevent loosening. |

| Vibration | Monitoring vibration levels to prevent failures. | Install vibration sensors for real-time monitoring. | Address any abnormal vibrations immediately. |

| Lubrication | Use of appropriate lubricants for couplings. | Select lubricants based on operating conditions. | Establish a regular lubrication schedule. |

Monitoring and evaluating machinery performance

after implementing hub coupling solutions

is crucial for maximizing efficiency and minimizing downtime. According to a recent report by the International Journal of Advanced Manufacturing Technology,

improper coupling can result in a 10-20% efficiency loss in machinery operations.

Therefore, after integrating advanced hub couplings, it's essential to implement a comprehensive monitoring system to track performance metrics such as vibration levels, temperature variations, and torque readings.

Data analytics plays a pivotal role in this evaluation process.

A study published by the Society of Manufacturing Engineers revealed that companies utilizing real-time data monitoring improve their

machinery reliability by up to 25%. By regularly analyzing the performance data collected post-implementation, engineers can identify anomalies, predict failures, and take proactive measures, thus extending the lifecycle of machinery.

Additionally, routine assessments can inform potential adjustments to improve alignment and balance, ensuring that the hub coupling operates within optimal parameters and enhancing overall operational productivity.